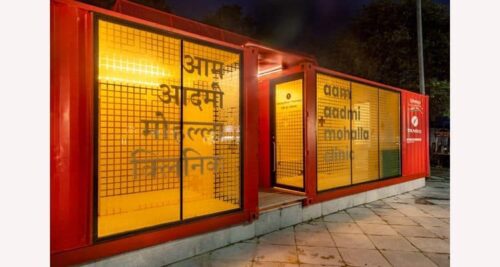

The clinic’s design is developed by Architecture Discipline and set up with the support of Tata Power-DDL for the Delhi government’s Aam Aadmi Mohalla Clinics programme

Delhi-based architecture firm Architecture Discipline has used upcycled shipping containers to create Mohalla Clinics, providing a compact, portable, and sleek primary healthcare solution for neighbourhoods in Delhi. In the first phase of deployment, two clinics have been installed in two urban settlements in Delhi: Shakur Basti and Rani Bagh.

The clinic’s design is developed by Architecture Discipline and set up with the support of Tata Power-DDL for the Delhi government’s Aam Aadmi Mohalla Clinics programme.

The Mohalla Clinics are built from shipping containers salvaged from various container yards in Delhi and Haryana. Two 20-foot-long containers are joined together to form a single clinic that includes an examination room, a reception and waiting area, a pharmacy accessible from outside, and a washroom. The clinic is fully equipped to support routine health checks, testing, and medicine purchasing.

The clinics are prefabricated and come preinstalled with electrical and lighting fixtures, essential interior finishes, and furniture. Their compact size allows them to be easily transported to various locations and be installed with minimal on-site construction.

The clinics’ interiors are oriented towards creating a hygienic and optimistic patient friendly environment, with air-conditioning and insulated walls that protect visitors from Delhi’s searing heat. Interior finishes such as the anti-microbial vinyl flooring and medical-grade stainless steel countertops are designed to be easy to maintain.

Akshat Bhatt, Principal architect of Architecture Discipline, said, “We have been experimenting with the use of shipping containers as a building material for a long time now, in typologies ranging from hotels to workspaces. Our own studio has an extension created out of a repurposed shipping container. This experience made the firm fairly proficient in the art of converting repurposed shipping containers into high-quality, usable spaces. Ever since the pandemic began, we have been exploring the potential of containers in creating healthcare facilities. We designed the Life Community Medical Facility (LifeCMF), a concept for a modular healthcare facility built out of shipping containers that was presented at the London Design Biennale 2021.”

“The Mohalla Clinics are a scaled-down version of LifeCMF, drawing on its central ideas of prefabrication, rapid deployability, and economic feasibility. The clinic’s design capitalizes on the structural strength of a discarded shipping container and works with it as a module, reducing the need for costly modifications or custom-built additions. In this manner, it redefines post-industrial waste as a medium for universal affordable healthcare. By taking something forgotten and giving it a new lease of life, the Mohalla Clinics present a sustainable solution for the health infrastructure crisis in our country”, he added.

Satyendar Jain, Minister of Health for the Government of Delhi tweeted, “We promised to give a quality healthcare system to Delhiites, and when we say ‘quality healthcare’, this is what we mean by it. Such clinics are easy to set up & transport in cluster areas like jhuggi-bastis & narrow streets where healthcare infrastructure is less accessible.”

Upcycled shipping containers: A sustainable building material

Intermodal shipping containers are steel containers of standardized dimensions, used in freight transport to carry a large number of items at once. Because of their durable steel body and structural integrity, these containers can be reused many times over and are ideal for a range of building applications. Reusing containers in buildings prevents the use of materials like cement and bricks, along with eliminating the carbon emissions occurring due to them. Hence, upcycled shipping containers are inherently sustainable in nature.

Design

Aimed at creating an optimistic and clean environment for patients, the interiors are thermally insulated for protection from heat and are lined with VOC-free plywood. Heat-resistant glass windows allow the clinic to be naturally lit without excessive heat ingress.

Interior finishes are designed to be easy to maintain, including the anti-microbial vinyl flooring and medical-grade stainless steel countertops. The clinic comes prefabricated with seating and storage spaces and is equipped with essential furniture like examination beds, wash basins, desks, tables, and chairs. Connected to the pharmacy, the washroom features a medical-grade stainless steel counter with a foot-operated wash basin, along with water-conserving plumbing fixtures.

The clinic is powered by server rack power strips and lit by under-lighting LED strips concealed with pelmets. An in-built air-conditioning system fitted with microfilters maintains air quality and filters out pollution, while maintaining comfortable internal temperatures.

Prefabrication and Construction

Composed of two 20-foot-long containers, the Mohalla Clinics can be entirely prefabricated and transported to their locations with a forklift, requiring minimal on-site assembly. Prefabrication enables greater quality control and precision in finishing, minimizing pollution due to construction activities and on-site errors.

The process of designing clinics from shipping containers is as follows:

With prefabrication, the clinics can be deployed rapidly, from 3-15 days depending on the time taken for container procurement. With factory production, this duration can even be brought down to 2-3 days. The quick construction of the prototype allows it to be deployed virtually anywhere, with the possibility of airlifting the units to emergency situations like disaster-struck regions or war zones.